Marketing is and always has been a sort of corporate cold war between products and ideas competing for consumer attention. One of the most important tools in the arsenal of any marketing team, therefore, are flexographic printers, inks, and storage units. Using these items to their fullest can help give you a definite advantage with superior professionally-printed items. Still, the question remains, just what are flexographic printers, inks, and tools, and which flex storage solutions can best preserve them?

1. What Are Flexographic Options?

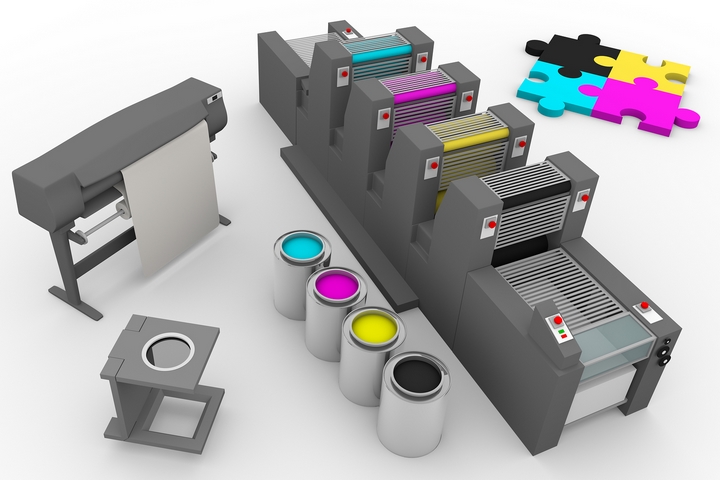

First thing’s first – what are these items, exactly? Flexographic printers and inks refer to tools and materials used in the production of banner and signage manufacturing which is, as the name would imply, rather “flexible.” This often allows flexographically printed materials to be pressed onto a wide range of different surfaces, from plastic bottles and signs to the sides of busses. Printers which can produce flexographic materials are thus a highly valuable asset for any marketing team to have.

2. Selecting the Right Ink

Now that we know what we’re working with, it’s time to clarify what types of ink we’re using. While there are several different types of inks, there are three main categories: solvent, water-based, and UV curable. Each of these inks has its own complex set of pros and cons, depending on both the chemical mixture of the particular inks, as well as the surface onto which they are going to be pressed. Take your time to figure out which inks are right for your intended use.

3. Handle with Care

Now let’s talk about the printers themselves. The most important thing to recognize about these printers is that they need to be handled with extreme care. Flexographic printing is a highly valuable process, but it’s also a somewhat delicate one. All it takes is for things to be off by just a little for everything to go very wrong. As such, you’ll want to follow some basic usage and cleaning tips, such as:

- Always be sure to minimize the amount of stress placed on the flexcart

- Avoid stacking sleeves and materials to be printed on the cart

- Take the time to clean and review the integrity of any and all sleeves before printing with them

- Check the statuses of the cartridges and your ink supply before printing for the best results

- Clean your flexographic printer regularly so as to avoid a buildup of oils and inks

4. Proper Storage

Last but not least, it’s fair to say that no discussion of flex storage solutions is complete without discussing the proper means by which to store these units. The last thing you want is for these units to degrade due to improper storage. Stacking your unit horizontally, for example, can lead to problems, namely, the sleeves used for printing falling out, bending under the pressure, or both. As such, vertical stacking has come to be the more commonly-accepted form of proper storage.

All of this and more can help ensure that your flexographic printer is kept in the best condition for years to come.