There are many methods to check food packages for leaks, and manufacturers are responsible for using the right leak detection equipment to ensure seal integrity. If freshness seals were routinely broken, everything from meats to veggies would spoil well before the “best used by” dates we all check. Here are five of the most common ways leaks are detected.

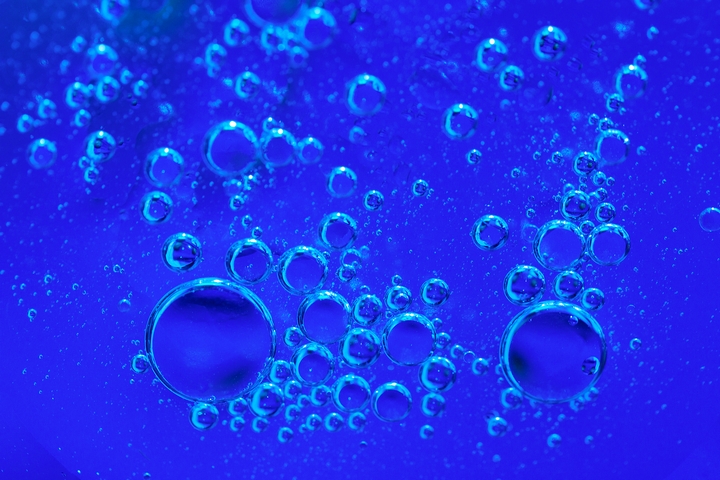

1. Immersion

Also called “bubble emission,” immersion testing is just what it sounds like. Packages are placed beneath the surface of some kind of liquid to see if any bubbles form along microtears in the material or gaps in the seal. The liquid in question is usually water, but specialized solutions also are also used to make bubbles more noticeable.

2. Pressure Chambers

This method comes in many forms including vacuum and altitude chambers. The basic idea is that the package is placed in an airtight chamber where the atmospheric pressure is altered in some way. Specialized leak detection equipment closely monitors the packaging to see if any air travels in or out of the sealed interior. Often, trace amounts of harmless gasses like helium and hydrogen are pumped into the chamber to aid in leak detection. For further information, Flexpak inc has online resources available on their website.

3. Dry Chambers

Similar to pressure chambers, dry chambers are airtight rooms that are kept free of moisture and foreign substances so that any leaks will be easier to spot. A sample package is brought into the room and placed on some kind of absorbent material. After a certain amount of time, the material is checked to determine if something that was inside the package has made its way out.

4. Machine Vision Systems

Leak detection equipment that uses some form of this system is quite common. However, sometimes machine vision is solely responsible for seal integrity inspection. Though this method is not the most reliable, machine vision is much more advanced than it was even a few years ago. High tech cameras can see infrared and ultraviolet light as well as zoom in incredibly close.

5. Ultrasonic Emission

If a bottle of soda is opened, it emits a hissing sound. Much smaller breakages also emit sounds; it just takes an extra sensitive ear to hear them. Ultrasonic leak detection equipment is programmed to listen for specific frequencies of noise at incredibly soft volumes to determine if a package is leaking. This method is by far the least common, but it is ideal for some types of packaging that contain gases under high pressures.

The best leak detection systems combine some or all of these methods to keep food fresh and safe to eat. Whatever the method, manufacturers rely on this technology to make sure customers can enjoy food without worrying about the freshness of unopened products.